-

Keywords"per",total

296 records

-

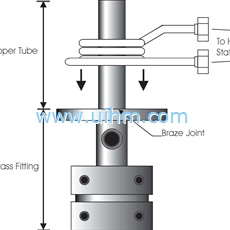

induction braze copper tube to brass fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300F…

-

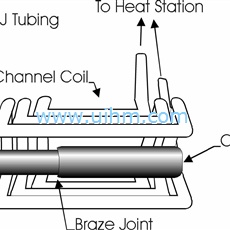

induction brazing copper tube

Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″ fitting in less than 10 seconds. Heating must take place in a channel type coil to allow for easy loading of parts. Material Copper Tubing and Fitting with Braze and Stay Silv White…

-

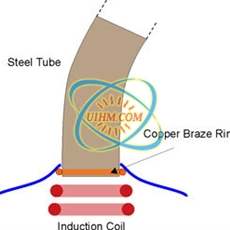

induction brazing steel tube with copper ring

Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850F (1010C) within 15 seconds for a brazing application. Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring. Tempe…

-

induction annealing copper tubing

Objective To heat both ends of a copper tube to anneal as soft as possible 1.5” (38.1mm) from end and retain full hardness next to anneal Material 1.625” (41.275mm) dia x 24” (609.6mm) long copper tube Temperature 1500 F (815.5 C) Frequency 70 kHz E…

-

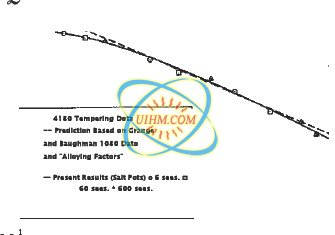

induction tempering of steel

The tempering of hardened steels is surely one of the most important of industrial heat-treating operations. For this reason, the mechanisms underlying the process as well as the effect of tempering on final mechanical properties have received wide attenti…

-

hardening and tempering of tool and die steels

Tool and die steels are covered in BS 4659:1989,although both American nomenclature and a variety of trade names are also in use. Available in high-quality grades, these specifically-designed steels can be grouped broadly according to their intended applic…