Induction Cap Seal Container Class: Other Induction Applications

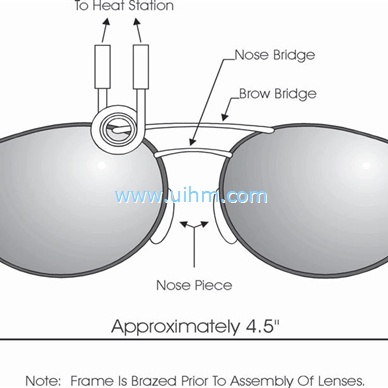

Induction Cap Seal Container Class: Other Induction Applications Intro: Objective To heat an aluminum in-cap laminate to a temperature of 350F in order to seal the laminate to the containerMaterial 3.5” (100mm)Temperature 350 F (177C)Frequency 300 kHzEquipment UM-UHF-4.5kW induction heating system; custom-designed work coil;

Induction Sealing aluminum foil to plastic bottle Class: Other Induction Applications

Induction Sealing aluminum foil to plastic bottle Class: Other Induction Applications Intro: Objective To seal a 1.5” (38.1mm) diameter cap with foil to a plastic bottle.Material 1.5” (38.1mm) diameter cap with 1.5” (38.1mm) diameter aluminum seal, plastic bottleTemperature 250-300 F (121-149 C)Frequency 309 kHzEquipment •UM-UHF-6kW induction …

Induction Brazing carbide to steel shaft Class: HF Induction Brazing

Induction Brazing carbide to steel shaft Class: HF Induction Brazing Intro: Objective Brazing a cone shaped carbide to a stainless steel shaft for a diggerMaterial Cone shaped carbide 1.12” (28.4mm) dia, 1.5”(38.1mm) tall, stainless steel shaft 1.12” (28.4mm) dia and various length, black brazing flux and braze shimsTemperature…

Induction Curing epoxy Class: Other Induction Applications

Induction Curing epoxy Class: Other Induction Applications Intro: Objective Heat the end of an aluminum copier roller to 400 F (200 C) to cure epoxyMaterial Aluminum roller 4.75” (120mm) diameter, 2’ (0.6m) long with 1.5” (38.1mm) thick plug at endTemperature 400 F (200 C)Frequency 52 kHzEquipment • UM-HF-25 kW induc…

Induction curing coating Class: Other Induction Applications

Induction curing coating Class: Other Induction Applications Intro: Objective Curing a coating on both sides of an aluminum piston at a rate of 1” (25.4mm) per secondMaterial 4 aluminum pistons weighing 1lb (.45kg) each, 3.75” (95.25mm) dia and 2.5” (63.5mm) highTemperature 225 F (107.2 C)Frequency 6 kHzEquipment • UM-…

Induction Curing adhesive Class: Other Induction Applications

Induction Curing adhesive Class: Other Induction Applications Intro: Objective To Cure adhesive in aluminum filter endsMaterial Aluminum filter, steel end caps & plastisol adhesiveTemperature 200 FFrequency 277 kHzEquipment UM-UHF-6kW induction heating system, equipped with a remote workhead containing two 0.1uF capac

Induction Curing Ceramic Fiber Class: Induction Tempering or Preheating

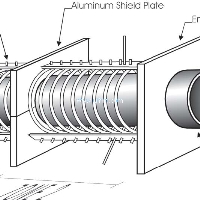

Induction Curing Ceramic Fiber Class: Induction Tempering or Preheating Intro: Objective To heat-cure a NextelTM Ceramic fiberMaterial Ceramic fiber 30,000 (9,145) ft(m) Steel tubeTemperature indicating paintTemperature 1300(700) F(C)Frequency 70 kHzEquipment UM-HF-45kW, 50-450 kHz solid-state induction power supply with a remote he

Induction Curing Paint Class: Induction Tempering or Preheating

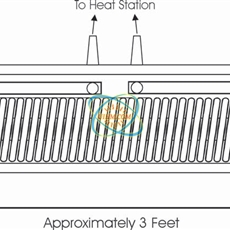

Induction Curing Paint Class: Induction Tempering or Preheating Intro: Objective To heat measuring tape stock at a maximum rate of 600 feet per minute to cure the applied paint. The heating coil is to accommodate the 3/8″ wide stock within the customer’s current framework. Curing must occur above 400F at the rate specified.…

Induction Bonding Solar Panels Class: Induction Bonding

Induction Bonding Solar Panels Class: Induction Bonding Intro: Objective To heat the stainless steel substrate of a solar panel shingle in order to melt the polymer encapsulant, allowing two shingles to bond together with a 3 inch overlap.Material 3″ by 10.25″ section of a 21″ solar panel shingleTemperature 130 CFr…

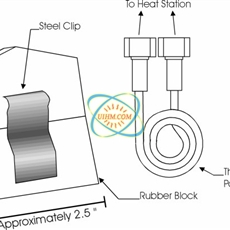

Induction Bonding Steel Clips Class: Induction Bonding

Induction Bonding Steel Clips Class: Induction Bonding Intro: Objective To heat metal clips and press-bond them into rubber seals. The metal needs to be heated to 250F to 350F with a cycle time not exceeding 3 secondsMaterial Steel clips and rubber sealer blocksTemperature 250F to 350FFrequency 373 kHzEquipment UM-U

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

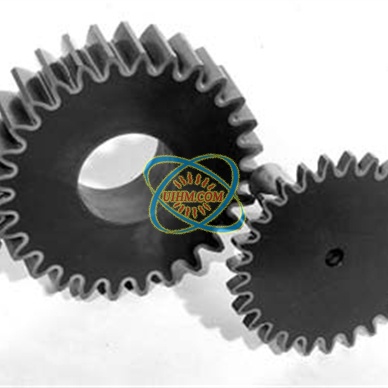

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar