Induction Soldering Fiber Optic Class: Induction Soldering

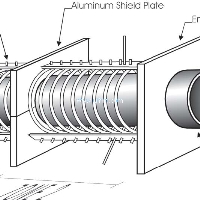

Induction Soldering Fiber Optic Class: Induction Soldering Intro: Soldering Fiber Optic Objective To heat a fiber optic housing to 400F within 10 seconds for avsoldering application, to form a hermetic sealMaterial Gold-plated aluminum housing, solder preform ring and fluxTemperature 400 FFrequency 267 kHzEquipment …

Induction soldering solar panel Class: Induction Soldering

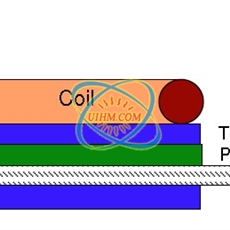

Induction soldering solar panel Class: Induction Soldering Intro: soldering solar panel Objective Heat multiple joints on solar flex circuit strips to 500F (260C) within ten seconds for a soldering application.Material Flexible solar panel, Solder Plus Paste 63NC-A, 0.0625” (1.59mm) thick Teflon sheetsTemperature 5…

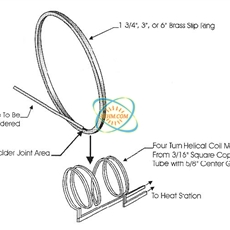

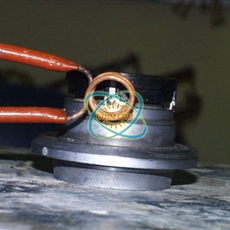

Induction Soldering brass rings Class: HF Induction Brass Solder

Induction Soldering brass rings Class: HF Induction Brass Solder Intro: Soldering brass rings Objective: To heat 1 3/4, 3 and 6 diameter brass slip rings and a sheathed copper wire assembly to 3600 F for soldering within three (3) to six (6) seconds. Currently production is accomplished by using a soldering iron and stick…

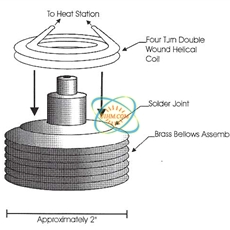

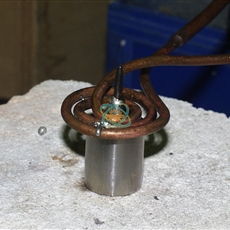

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder

Induction Soldering Brass Bellows Assembly Class: HF Induction Brass Solder Intro: Soldering Brass Bellows Assembly Objective: To heat a brass bellows and end cap assembly to 450F for soldering within 20 seconds. Presently, a soldering iron is used to produce the joint between the bellows and cap. The customer requests a quality sol…

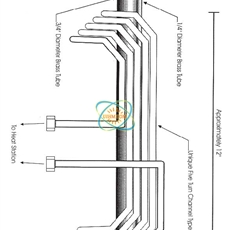

Induction Soldering brass tubes Class: HF Induction Brass Solder

Induction Soldering brass tubes Class: HF Induction Brass Solder Intro: Soldering brass tubes Objective: Soldering two brass tubes measuring 3/4 and 1/4 together for use as cellular phone antennas. The lengths of tubes range from four (4) feet to twelve (12) feet, and must be soldered along the axial side. The joint is to…

Induction Soldering Steel Class: Induction Soldering

Induction Soldering Steel Class: Induction Soldering Intro: Soldering Steel Objective To heat a special steel housing to 500(260) F(C) for a soldering applicationMaterial Steel housingSolder wire and fluxTemperature 500(260) 550(287.8) F(C)Frequency 200 kHzEquipment Power of 6kW, 150-400 kHz solid state induc…

Induction Soldering Steel Tube Class: Induction Soldering

Induction Soldering Steel Tube Class: Induction Soldering Intro: Soldering Steel Tube Objective Heat a.125” (3.175mm) diameter stainless steel tube to a 1” diameter cylinder 1” (25.4mm) tall for a soldering applicationMaterial Stainless steel cylinder and tubeTemperature indicating paint Lead free solder preform…

Induction Soldering copper Class: Induction Soldering

Induction Soldering copper Class: Induction Soldering Intro: Soldering copperObjective Heat copper tab until the solder reflows.Material Copper tab 0.25 X 0.25 inch square about 0.05 inches thick.Lead free solder material (higher melting temperature than regular solder.)Temperature 500 F for 1.25 secondsFrequen…

Induction Shrink Fit Cast Iron Class: Induction Shrink Fitting

Induction Shrink Fit Cast Iron Class: Induction Shrink Fitting Intro: Shrink Fit Cast Iron Objective To use induction to prepare cast iron assemblies for shrink fit assemblyMaterial Customer supplied cast iron rocker arms of varying sizesTemperature 450 F (232 C)Process Time 20 secondsFrequency 48 kHzEquipment Power of …

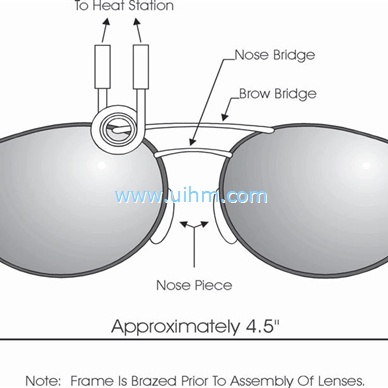

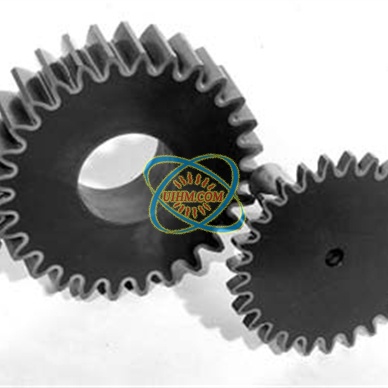

Induction Shrink fit steel gear Class: Induction Shrink Fitting

Induction Shrink fit steel gear Class: Induction Shrink Fitting Intro: Shrink fit steel gear Objective Heat the bore of a hardened spur steel gear to shrink fit onto a gear motor shaft. This is part of a chair for the disabled.Material Steel gear 2.5 h (63.5mm) OD, .75 h (19mm) ID x .625 h (16mm) thick, temperature indic…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar