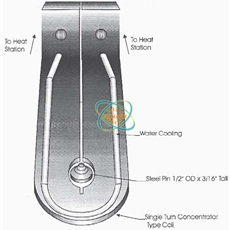

Induction Heating Inconnel Susceptor Class: Other Induction Applications

Induction Heating Inconnel Susceptor Class: Other Induction Applications Intro: Heating Inconnel Susceptor Objective: Heat an Inconnel susceptor to 19500F in less than one (1) minute for heating jet engine fan blades. This approach is to be used, instead of directly heating the blade, since improved temperature uniformity will be…

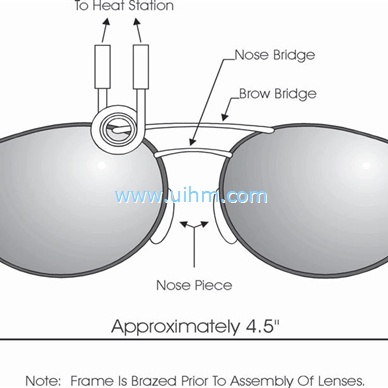

Induction Heat Television Picture Tube Glass Class: HF Induction Brazing

Induction Heat Television Picture Tube Glass Class: HF Induction Brazing Intro: Heat Television Picture Tube Glass Objective: The incorporation of solid state RF induction heating into the television picture tube industry, specifically the insertion of attachment pins into the already formed picture tube glass panel. Four pins ar…

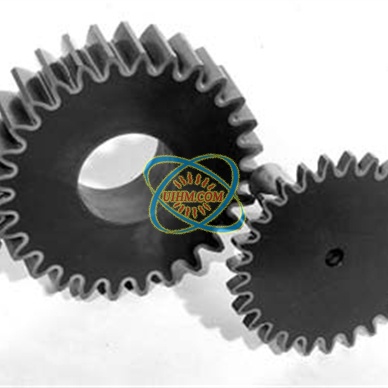

Induction Shrink Fitting Cam Shaft Gears Class: Induction Shrink Fitting

Induction Shrink Fitting Cam Shaft Gears Class: Induction Shrink Fitting Intro: Shrink Fitting Cam Shaft Gears Objective To heat aluminum and steel camshaft gears to over 500F within 4 minutes for a shrink fitting application.Material 6” diameter, 2” thick steel and aluminum camshaft gears, “K” type thermocouple, digital ther…

Induction Shrink fit steel ring Class: Induction Shrink Fitting

Induction Shrink fit steel ring Class: Induction Shrink Fitting Intro: Shrink fit steel ring Objective Heating a steel band to 1000 F (538 C) and inserting a carbon graphite ring in the center of the steel bandMaterial 4340 steel ring 8” (20.3cm) OD x 7.75” (19.7cm) ID, .895” (22.7mm) thick, carbon graphite ring inser…

Induction Shrink Fit Bearings Class: Induction Shrink Fitting

Induction Shrink Fit Bearings Class: Induction Shrink Fitting Intro: Shrink Fit Bearings Objective To heat a roller bearing assembly for a shrink fitting applicationMaterial Steel bearings, diameters 1” to 3.5” (25.4 to 89mm)Temperature 300F (150C)Frequency 60 kHzEquipment Power of 25kW solid-state induction power su…

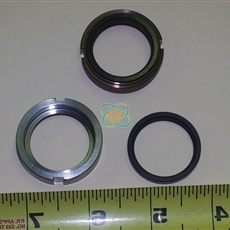

Induction Shrink Fit Steel Flange Class: Induction Shrink Fitting

Induction Shrink Fit Steel Flange Class: Induction Shrink Fitting Intro: Shrink Fit Steel Flange Objective To heat steel flange for heat shrink application. Reaching the desired temperature results in adequate expansion to allow for placing of the flange over a graphite seal.Material Graphite seal 1” (25.4mm) diameter ste…

Induction Shrink Fit Steel Tube Class: Induction Shrink Fitting

Induction Shrink Fit Steel Tube Class: Induction Shrink Fitting Intro: Shrink Fit Steel Tube Objective Heating a steel tube to 500-1000F for a shrink-fitting application. Determine expansion (growth) of ID at varying temperatures.Material Steel tubes 7” OD x 4.75” ID x 5” heat zone Type ‘K’ thermocouple to measure t…

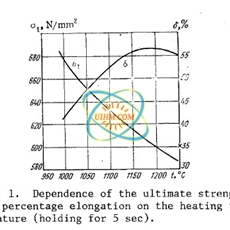

INDUCTION HARDENING OF BEARING PARTS Class: Induction Hardening

INDUCTION HARDENING OF BEARING PARTS Class: Induction Hardening Intro: INDUCTION HARDENING OF BEARING PARTS It is known that induction heating is effective in flow-line mass production that precludesresetting of equipment, or in individual production where the application of ordinaryheating methods is difficult.Induction…

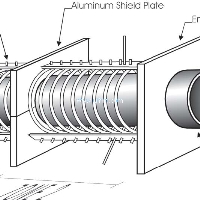

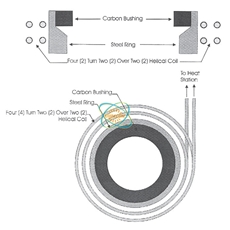

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Class: Induction Heat Treatment

HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Class: Induction Heat Treatment Intro: HEAT TREATMENT WITH INDUCTION HEATING OF WITHIN PIPES Electrically welded pipes with an external diameter of 16-102 mm made from corrosionresistantsteels of the austenitic class after having been made on argon-arc welding mill(AAW) are at present heat…

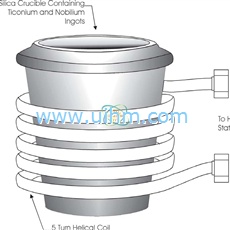

Induction Melting Ticonium and Nobilium Class: Induction Melting

Induction Melting Ticonium and Nobilium Class: Induction Melting Intro: Melting Ticonium and Nobilium Objective: Crucible melting of Ticonium and Nobilium ingots within a period of 45 seconds. Four ingots of Nobilium are to be placed in a crucible (ID#6012) and heated, while a single ingot of Ticonium is placed in a cruci…

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar