Induction Shrink fitting carbide ring Class: Induction Shrink Fitting

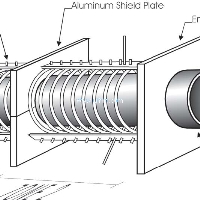

Induction Shrink fitting carbide ring Class: Induction Shrink Fitting Intro: Shrink fitting carbide ring Objective Shrink fitting a carbide ring into a steel valve seatMaterial Steel valve seat 6” (152.4mm) OD with 3” (76.2mm) ID hole & .75” (19mm) thick, carbide ringTemperature 500 F ( 260 C)Frequency 55 kHzEquipment •…

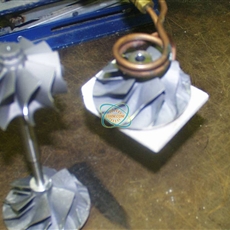

Induction Shrink fitting impeller blades to shaft Class: Induction Shrink Fitting

Induction Shrink fitting impeller blades to shaft Class: Induction Shrink Fitting Intro: Shrink fitting impeller blades to shaft Objective Heat aluminum impeller blades to 200 F (93 C) and shrink fit onto a shaft.Material Aluminum impeller blades with a .28” (7.109mm) bore, aluminum shaftTemperature 200 F (93 C)Frequency 255 kHzEquipment…

Induction Shrink fitting pulley to insert bearing Class: Induction Shrink Fitting

Induction Shrink fitting pulley to insert bearing Class: Induction Shrink Fitting Intro: Shrink fitting pulley to insert bearing Objective Heat aluminum pulley for insertion of an inner bearing for the automotive industryMaterial Aluminum pulley 2.3” (60mm) OD x 1.6” (40mm) ID x 1” (27mm) high and inner bearing 0.7” (17.8mm) high x 1.…

Induction Shrink fitting wrist pin into connecting rod Class: Induction Shrink Fitting

Induction Shrink fitting wrist pin into connecting rod Class: Induction Shrink Fitting Intro: Shrink fitting wrist pin into connecting rod Objective Assemble connecting rods with a more accurate control of the heatMaterial Rod has an OD of .9125” (23.18mm), knuckle has an ID of .9125” (23.18mm) with an interference of .0001” (.0025mm). Knuc…

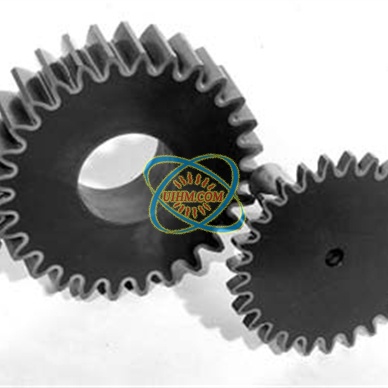

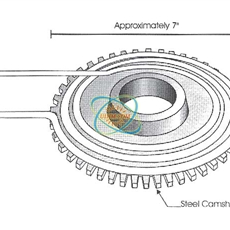

Induction Shrink Fit Camshaft Gear Class: Induction Shrink Fitting

Induction Shrink Fit Camshaft Gear Class: Induction Shrink Fitting Intro: Shrink Fit Camshaft Gear Objective: Heating a camshaft gear with a bore size of 1.630 to shrink fit over a steel shaft that has a diameter of 1.632. A temperature of 5000F is required for the gear to expand 0.002 in order to slip over the shaft. Produ…

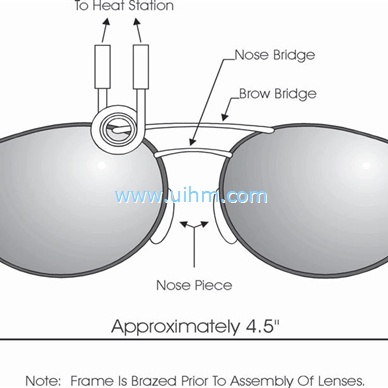

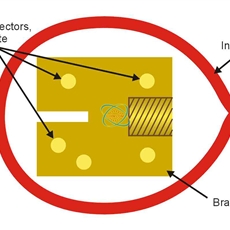

Induction Soldering Steel Connectors Class: Induction Soldering

Induction Soldering Steel Connectors Class: Induction Soldering Intro: Soldering Steel ConnectorsObjective Heat an assembly of small, gold-plated steel connectors to a brass block.Material Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass blockTemperature 600F(315.6C)Freq…

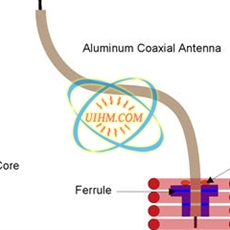

Induction Soldering Radio Antenna Class: Induction Soldering

Induction Soldering Radio Antenna Class: Induction Soldering Intro: Soldering Radio AntennaObjective To heat a coaxial antenna assembly to 600F within 2 seconds for a soldering application. The goal to improve on an existing procedure with a soldering iron which required 10 to 15 seconds.Material .250” diameter alumi…

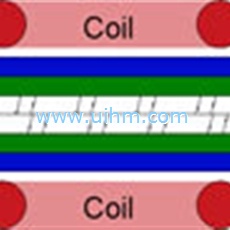

Induction Solder Flex Circuits Class: HF Induction Brazing

Induction Solder Flex Circuits Class: HF Induction Brazing Intro: Solder Flex Circuits Objective To heat multiple joints on flex circuit strips to 180-200F within seven seconds for a soldering application.Material Copper bonded to polyester flex circuit strips, Solder Plus Paste 63NC-A, 0.0625” thick Teflon sheetsT…

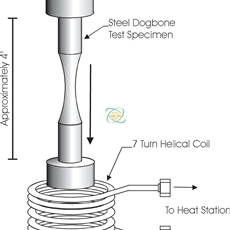

Induction Heating Steel Dogbone Specimen Class: Other Induction Applications

Induction Heating Steel Dogbone Specimen Class: Other Induction Applications Intro: Heating Steel Dogbone Specimen Objective: To heat a magnetic steel dogbone specimen to 12000F as quickly as possible and sustained for tensile testing. Heating should take place using a helical coil placed square in relation to the long axis of the ga…

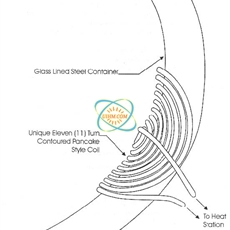

Induction Heating Repair Lined Steel Tank Class: Other Induction Applications

Induction Heating Repair Lined Steel Tank Class: Other Induction Applications Intro: Heating Repair Lined Steel Tank Objective: To heat selected areas of a glass lined steel tank to 16000F in order to perform repairs of cracks and chips. The glass is used as a frit which must be reflowed and filled into the damaged areas. Temperature …

Recommended

induction brazing diamond segment

induction shrink fitting for Automotive cylinder rod

induction heating drill pipe by twin coils

Ball stud high-frequency induction hardening

Splined shaft induction hardening

Sprocket induction hardening

Gear shaft induction hardening

High frequency induction brazing welding steel bar